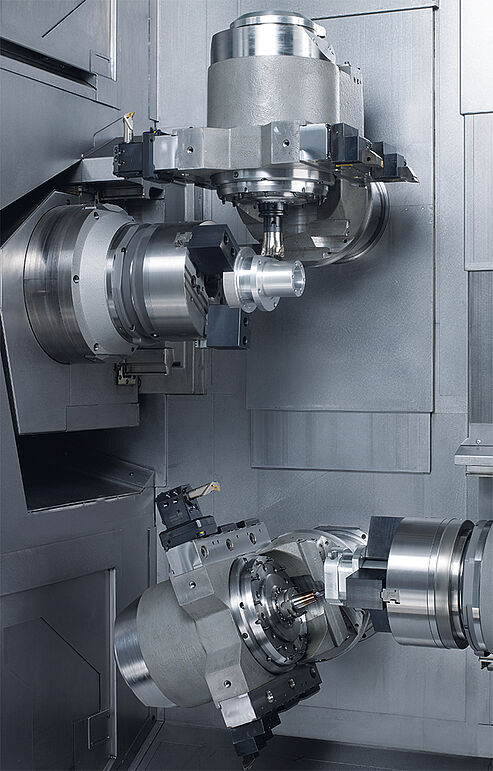

R300 turn-mill center – a new dimension

5-axis milling and turning in a new dimension

Machine highlights

Your benefits

- Change up to 140 tools (HSK-T63) in 6 seconds chip-to-chip time – thereby shortening secondary processing times at both spindles

- Two full 5-axis systems in a turn-mill center

- Extensive automation options – tailored to the individual customer needs

- X travel ranges of up to 780 mm

R300 in the focus

The magazine – all tools on board

With up to 140 magazine stations, tools can be changed in only 6 sec chip-to-chip time on both spindles. The tool loading strip allows even more productivity gains by changing 8 tools during machining.

- 70/140 tool stations (HSK-T63 mounting)

- Shortest change cycles; chip-to-chip time only 6 s

- Simultaneous and independent loading of both milling spindles possible

- High degree of functional reliability due to standard tool magazine with chain design

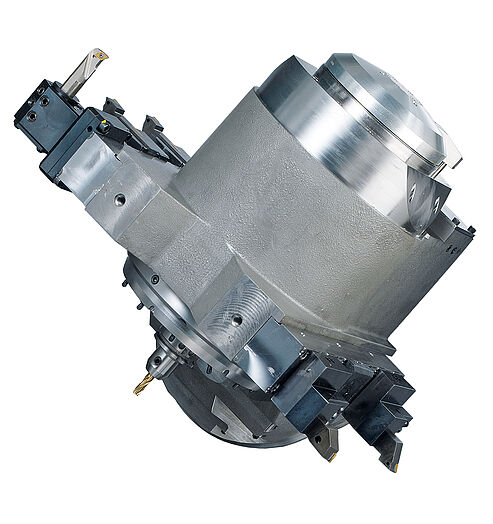

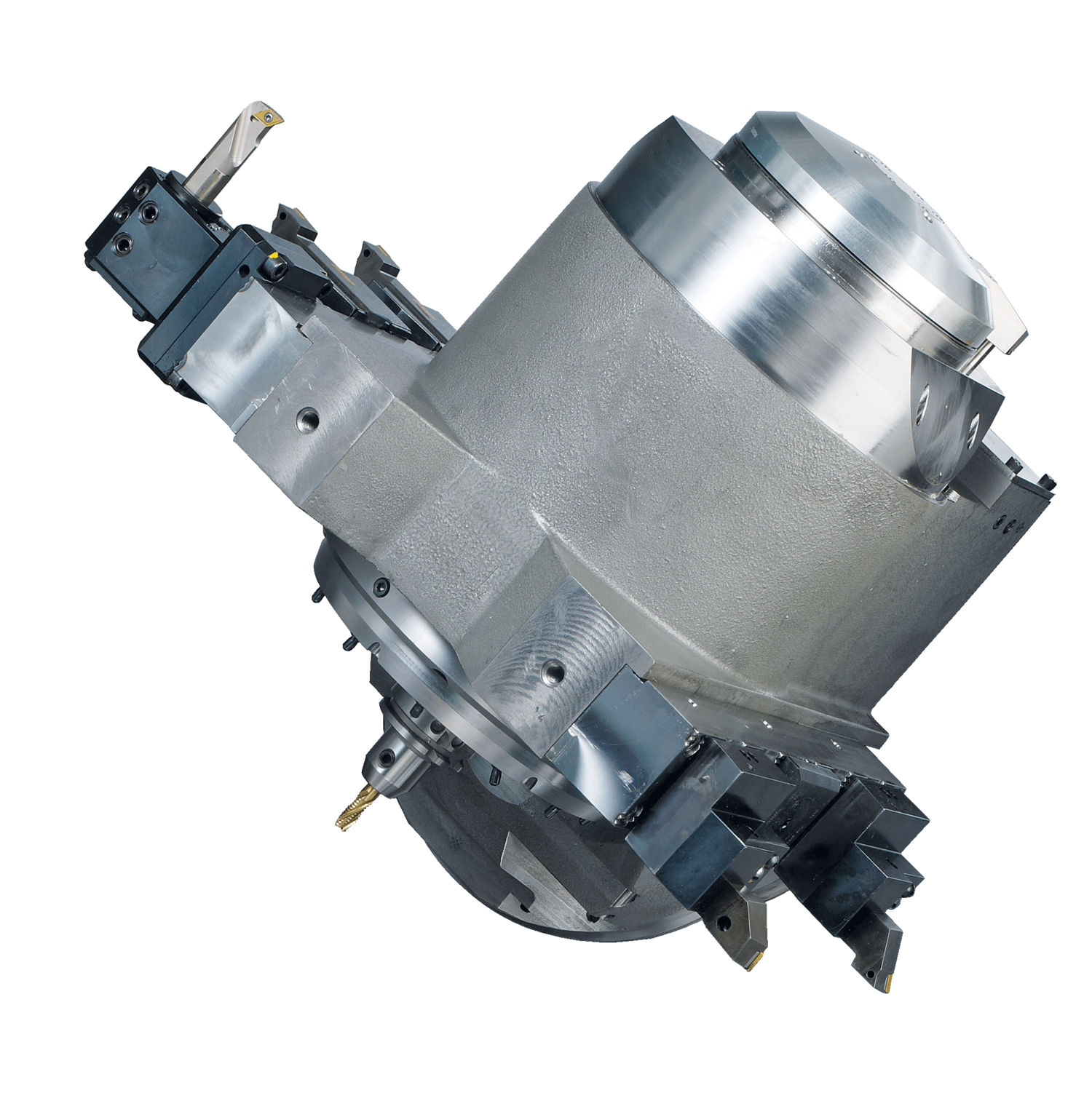

The motorized milling spindle

95 Nm powerful torque

The arrangement of the milling spindles in the middle of the machine bed ensures transmission of force via particularly short lever arms. This results in high vibration damping and hence prolonged tool life.

The advantage for you:

Better workpiece quality and reduced costs over the entire life cycle of the machine.